This week I was invited to present at the virtual ICoTA Week and I was delighted to share how we are moving forward with our Digital Transformation Roadmap.

Digital transformation is already a fact of life for many of us. The demands to re-wire an inefficient value chain present us with a real opportunity to create value and change the way we operate. We believe the time is right to reconfigure the operating model, make a step change in connectivity and digital collaboration and bring the extensive expertise and data we have at our disposal onshore into a real-time dynamic with our operations offshore and in the well.

It’s a broad subject. In my presentation I picked three things: connectivity, data priorities and emerging operating applications, with a view to highlighting how we can accelerate the use of data and in-turn operationalise into our delivery model.

Connectivity

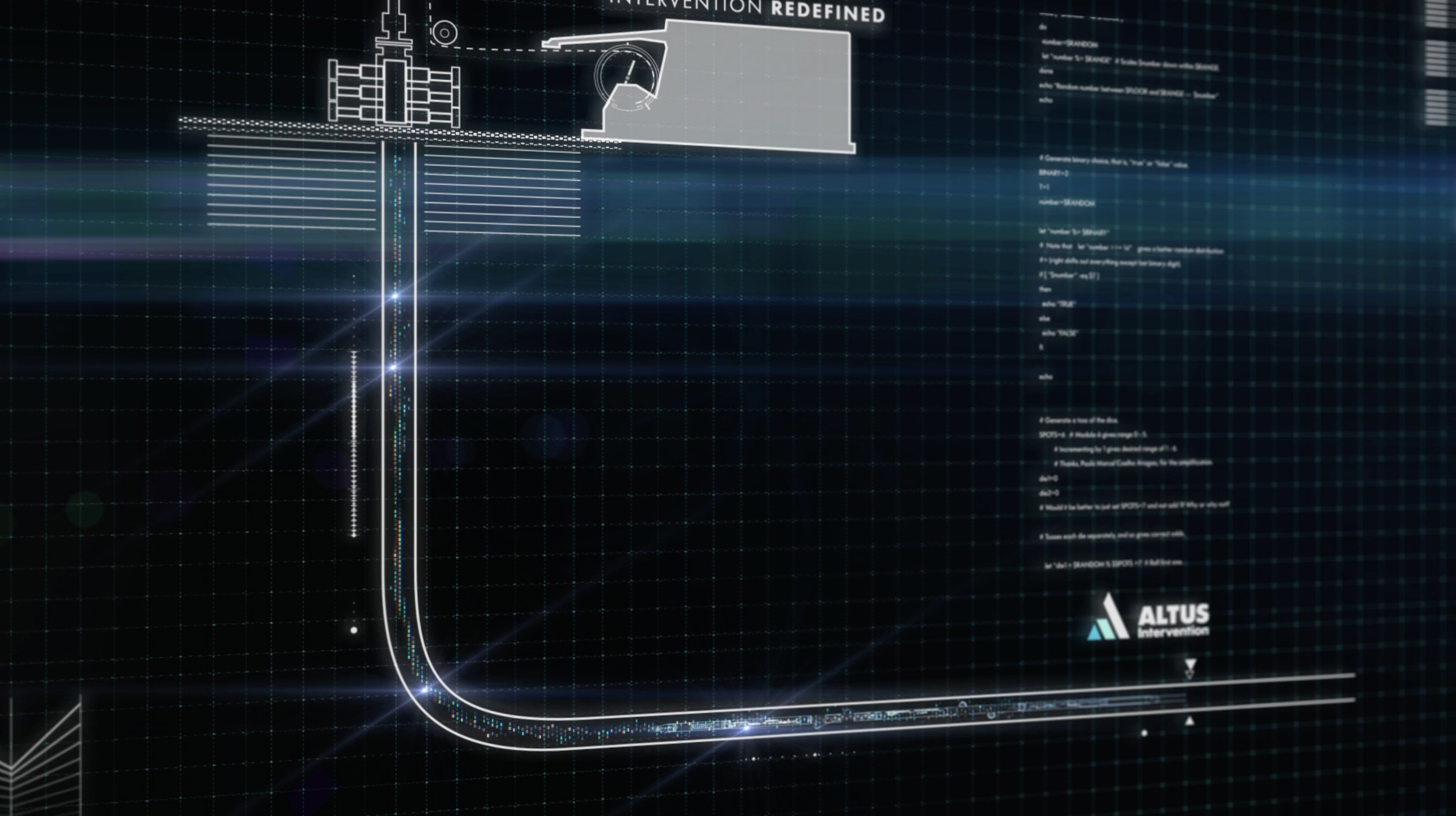

In everyday life, we take good digital connectivity for granted, e.g. working from home or live streaming videos on our mobile. Our vision is that this should also be the case for offshore operations. We have seen tremendous development in the infrastructure offshore recently that will help take our well intervention operations a step forward. For example, using data, voice and video consistently throughout the operation, from downhole (using sensors, instrumentation and advanced telemetry in tools) to topside delivery equipment and then to onshore – always connected. This will support a move towards remote operations and connecting onshore experts to the job, live.

With this in mind, we have focussed on building an open architecture that will allow secure multi-party collaboration and data integration, allowing us to replicate any scenario or view of what is happening in real-time onshore. We can then evaluate this data together with our clients and service partners live – making decisions increasingly data driven and more efficient.

Data priorities

With our PRIME Technology Platform we are already transforming access to downhole tool data that is crucial for managing successful jobs. The high degree of instrumentation and sensors provide critical tool and task parameter intelligence. For example, if you have milling job with a specific target, we can see all the data relating to what’s happening, in real-time, including weight on bit, torque and RPM. Combining this with data from the WL winch during conveyance (e.g. speed, tension depth) or specialist diagnostic well condition logging tools, provides those involved in the operation a clear and accurate picture of the encountered conditions – which can vary widely well to well.

The open architecture of the platform allows third party integration so that we can aggregate the data in one system and create intelligent dashboards and applications to support the job as a whole. The accurate capture of the data in a well-structured manner in-turn offers huge opportunities to bring valuable intelligence from other operations into how we handle the task literally at the click of a button or as the technology develops, bringing machine learning or AI parameters into real-time performance. Today with our Prime Technology Platform we are accessing data from sensors in the tools and using that to influence real-time commands downhole – this is what we mean by operationalising data – the impact has been amazing, facilitating surgical precision 1000s of metres under the surface.

Operational Applications – transforming the way we work

Our digital well intervention platform will significantly affect all parts of the intervention value chain and change the way people do their everyday job. Examples of functionality we are implementing include:-

- Planning: - the planning process will be a streamlined workflow with integrated data platforms to extract relevant data and perform the needed simulations. We see this not only improving quality but enabling a reduction in planning activity from weeks to days and hours.

- Execution: - the impact of live dashboards with key data and intelligent visualisation not only pave the way to “remote operations” but allow the expert collaboration and support in real-time. The ability to adapt to encountered conditions with advanced downhole technology is a game changer in task certainty – reducing costly time in hole and number of runs.

- Reporting: - from planning to completion it is often the case that valuable job data is managed and controlled in silo systems making the accuracy, quality and effort involved variable and inefficient. Taking an end to end approach – the reporting is largely automated, data is captured and job reporting uniform.

We aspire to become the digital front runner in the well intervention industry and transform the intervention value chain together with our customers. This needs a new level of collaboration and I am delighted at the progress we are making. Our clients see the opportunity clearly and we have real momentum.